Process analytical technology

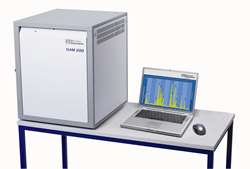

Aage Christensen offers different types of process analytical technology, such as FTIR equipment for measurement of liquids and gas analyzers for measurement of gases in everything from fermenters to flue gas plants.

If you wish to know more or have questions, please do not hesitate to contact us.